How to calculate your carpet carbon footprint

As a carpet manufacturer, measuring your carbon footprint is the first step towards reducing your climate impact. However, with so many factors influencing the result, calculating your carbon footprint can seem like an insurmountable task. You probably know what happens within your own company walls, but how do you take into account emissions over which you have no control, like those coming from suppliers or end users? Let’s shed some light on this matter.

The final evaluation of the recent COP27 Climate Change Conference couldn’t be clearer: our planet is still in the emergency room. The red line we must not cross is the line that takes our planet over the 1.5-degree temperature limit. To have any hope of keeping to 1.5, we need to massively invest in renewables and reduce our carbon footprint.

To get this out of the way first: carbon footprint relates to much more than the so often mentioned CO2 emissions. Carbon-containing gases also include methane (CH4), nitrous oxide (N2O), and others, some of which are many times more potent at heating the atmosphere. Carbon footprint is the total amount of greenhouse gases emissions caused by an individual, event, organization, service, place or product, expressed as carbon dioxide equivalent (CO2eq.).

The complexity of carbon footprint

That said, the industry can no longer ignore its own role in this story. Today, consumers simply demand more sustainable products and legislation is also getting stricter. However, to successfully reduce carbon footprint, organizations first need to know where they stand. They need to know their most important sources of greenhouse gas emissions, so they can make changes where impact is the greatest. However, in practice, this is not so simple.

Say you are a carpet tile manufacturer. It may be relatively easy to look at the impact your own production system is having. You know the energy it needs to get your products manufactured and you can calculate the cost of transport.

But obviously, your product does not live in a vacuum. It is made of raw materials you buy from suppliers. And once your product is manufactured, which involves diverse materials, packaging and waste, it is used and ultimately disposed of, either on landfills or by incineration. Some of those factors are in your control, some aren’t. But all of them have an impact on the total carbon calculation.

The life cycle of a carpet

Let’s stick to the carpet example. To make correct carbon footprint calculations, we need to look at the entire life cycle of a carpet. This is done – you guessed it – in a Life Cycle Analysis (LCA). The LCA is a tool to evaluate the environmental impact of a product or process over a defined life cycle period, and it’s important input for the Environmental Product Declaration (EPD).

Typically, a carpet product life cycle consists of five stages:

- Raw material extraction: The most obvious raw materials used in carpets are yarns, such as polyamide (PA) and polyethylene (PET) yarns. The carbon intensities for each type of yarn will be different. Possible emission sources that need to be taken into account are the extraction of oil in case of synthetic yarns, energy used for yarn manufacturing, and water usage. Recycled yarn materials can also be used in this stage.

- Manufacturing & processing: This stage comprises carpet tufting and finishing. All energy used during these processes needs to be taken into account, as well as the use of water, and generation of waste.

- Transportation: This includes the transportation of raw materials and of the end product, as well as the distribution of the carpet.

- Usage & maintenance: This includes the number of times a carpet is washed and dried during its lifetime.

- Waste management: Historically, carpet waste is either used for energy recovery or landfilled with very limited recycling taking place. Fortunately, there is a positive evolution towards more carpet recycling and more carpet eco-design (design with the end of life in mind), contributing to a more sustainable, circular economy.

You would think that every LCA considers all five stages, but that is not the case. Some assessments consider the entire life cycle, some only parts of the life cycle. In other words, they apply different system boundaries.

The most cited methods are cradle-to-gate and cradle-to-grave. A cradle-to-gate assessment will only include the product impact caused from the resource extraction (cradle) to the factory gate (i.e. before it is transported to the consumer). Cradle-to-grave on the other hand considers the full life cycle, from resource extraction (cradle) to use phase and disposal phase (grave).

Considering the entire value chain

End of story? Not yet. Although most carpet manufacturers are already looking at reducing emissions from their own operations, the majority of emissions typically comes from the value chain, in the case of synthetic carpets, from the production of polymers for example. The polymer is responsible for about 50% of a carpet tile’s cradle-to-gate emissions.

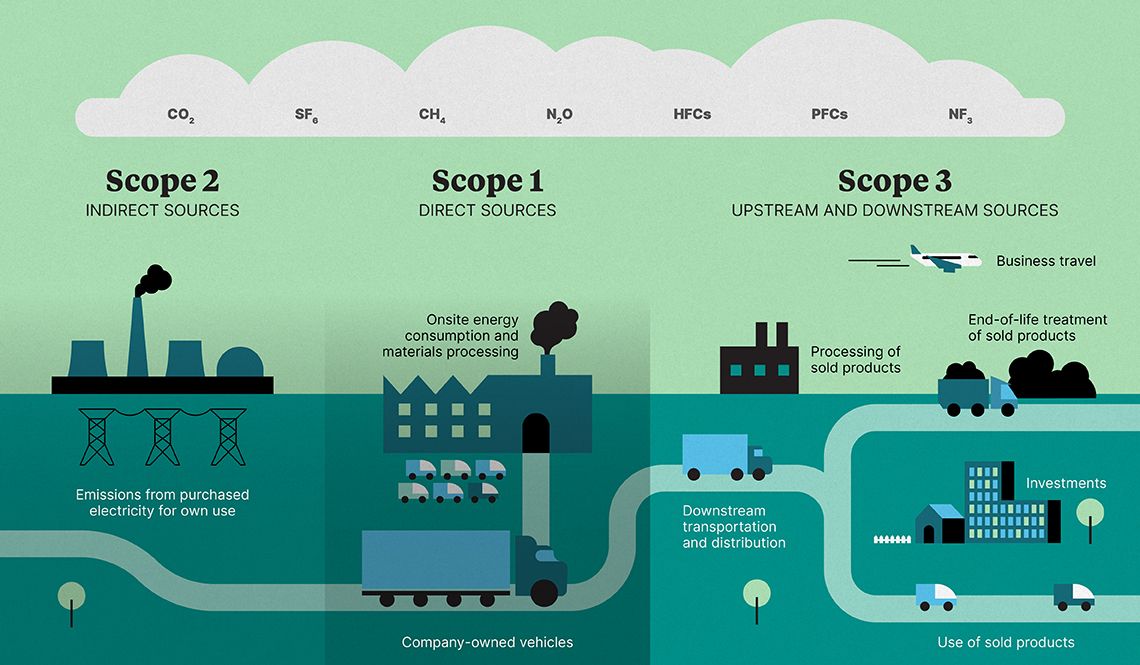

The value chain is typically presented in different scopes. These scopes allow organizations to identify the impact they make based on everything they need to operate.

- Scope 1: These are direct emissions coming from vehicles and the factory, including all energy needed to keep operations going.

- Scope 2: These are indirect emissions resulting from bought electricity, cooling or heat.

- Scope 3: These include other indirect emissions that occur in the value chain of a company that are not already included in scope 2. This can come from upstream activities (e.g. emissions coming from purchased goods and services or transport) or downstream activities (e.g. the impact resulting from incineration or landfilling).

Scope 1 and 2 emissions are easier to measure. Scope 3 emissions on the other hand are the most complex category to accurately and fully measure in carbon accounting. According to many sources, more than 90% of emissions are generated by the entire value chain. If carpet manufacturers want to be serious about carbon footprint reduction, they will need to look at the entire picture.

It’s complicated, but not impossible

Obviously, the first step to gaining insight into your carbon footprint is to look into your own operations and within your own company walls. However, if you want a more complete picture, you will need to measure the emissions coming from your value chain as well, both upstream and downstream.

Correct and comprehensive carbon footprint calculations will enable you to identify the hotspots of your environmental impact. Based on this information, your organization will be able to make more sustainable buying choices, or even develop a strategy to engage your suppliers towards more sustainable options.

Fortunately, there are options available, for example in the production of yarns. The chemical industry is already offering sustainable alternatives to traditional polymer production – an important material for yarn manufacturing – by using bio-based materials instead of fossil-based sources. Including these sustainable yarn solutions into their designs, carpet manufacturers can reduce their own carpet footprint much faster.

Looking downstream, carpet manufacturers can look into more sustainable end-of-life scenarios. The idea of the circular economy is already gaining traction. More carpet manufacturers today are embracing the concept of eco-design to develop products that just last longer. In this model, products no longer need to end up as waste, but they can be repurposed into something new.

Reducing carbon footprint may be complex, but it’s far from impossible.